What Is BGA Soldering And How does It Works

BGA soldering is a complex thing to understand for beginners. Now, you don’t have to worry. In this article, we will cover all the necessary information regarding the same. As technology is increasing faster than before, the demand for small device sizes has risen. All the smartphones and other gadgets consist of BGAs. Therefore, the Ball Grid Array packages are necessary to produce. Its industry is also growing due to this reason.

Many people don’t know much about BGA. If you are in the same situation, it is essential to understand it first before moving on to its soldering process. You might be curious to get sufficient knowledge about it, and you can learn more. Ball Grid Array soldering is a significant process that everybody needs to know. It has become much easier to find valuable information on the web. Also, we are here to help you. So, without wasting any more time, let’s get started with it.

What is BGA?

A Ball Grid Array is a type of package for Surface Mount Technology. It has metal ball alloys that are arranged in a grid pattern. One can also perceive it by the name. There are no wires in it; instead, you will see balls of solder on the surface. You will be surprised to know that there are different types of BGA used for various purposes.

What are the features of the Ball Grid Array?

The unique features of BGA are as follows:

- The interconnection density is pretty impressive.

- It is small and concise. So, it doesn’t take up more space on the circuit board.

- Placement problems don’t occur.

- The thermal resistance is low between the package and the PCB. As a result, it protects the chip from overheating.

What are the various types of Ball Grid Arrays?

As we mentioned earlier, you will find a wide variety of BGAs in the market. We have prepared a list of the most popular ones-

- Plastic ball grid arrays: They are also known as OMPACs (Over Moulded Plastic Array Carriers). A type of PCB material is used in the production of PBGA. All the solder balls on their surface are around 0.5 to 0.7mm in diameter.

- Tape ball grid arrays: It has not been so much time since TBGA got introduced. So, it is new in the market. A carrier, metal layer, and copper tape are included in them. The metal layer is on the top and doesn’t consist of anything. Therefore, it is a plane surface. But the bottom part has copper lines that are connected to the solder balls.

- Ceramic ball grid arrays: CBGAs are also known as SBCs (solder ball carriers). It has a die connected to the ceramic multilayer’s surface. The solder balls present use an increased amount of temperature.

- Ceramic column grid arrays: They are an alternative for CBGAs. It consists of solder columns attached to the bottom side of the carrier.

How is BGA soldering done?

When BGA components came into the market, everybody was doubtful if they would work or not. But now people know how important they are for producing small devices and gadgets.

Various types of BGA soldering techniques are tested many times. So, you don’t have to worry about its consequences. Also, a BGA solder is considered more reliable than the SMD package solder. One of the most effective is the Reflow soldering technique.

Reflow soldering technique: In this technique, the temperature of PCB assembly is set up to melt the solder balls under the BGA components. All the solder balls contain a certain amount of solder, generally 18, 24, or 30 mils. The solder melts when the board gets heated due to the BGA package placed inside the reflow oven.

How to inspect the BGA solder joint?

It is a pretty challenging task to inspect the BGA solder joint. The primary reason behind the same is that the solder is not visible from the outside. However, you can find them through solder joint X-rays. X-rays will let you know the location of the joints more precisely.

What are the steps involved in BGA soldering by hand?

If you are planning to do BGA soldering by your hand, you need to follow these steps:

- Use hot air: The temperature needs to be a bit high while you are starting the process. You can use hot air for the same.

- Remove the BGA package: The next step is to remove the BGA package. Also, clean the board and its pad. You need to make sure there is not any excess solder on the board.

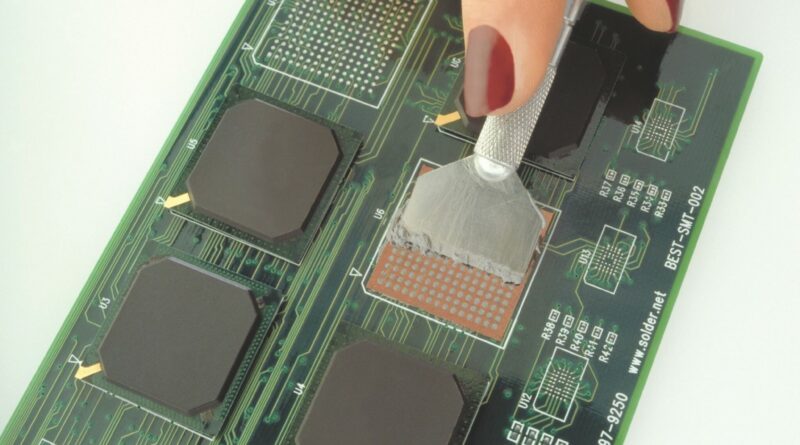

- Apply flux paste: Flux paste is helpful in the process because it is effective for pasting the balls. Problems might arise if they are not fixed correctly.

- The proper placement is necessary: All the balls must be appropriately placed on the pad if you don’t want to make mistakes. After that, put the BGA package on the balls after applying flux paste.

- Heat the package: The last step is to heat the BGA through hot air lower from both sides (i.e., top and the bottom). In this way, all the balls will melt, and your soldering will be done.

What are the precautions one needs to take during the soldering process?

The process of soldering might seem like an easy task. But it is not. Some issues might arise if you don’t consider the following precautions:

- Sufficient heat: A good amount of heat should be there. Otherwise, the balls won’t get melted, and all your hard work will get wasted. It is essential to use a good quality hot air blower.

- Take care of the temperature: The joints will be solid if you take care of the temperature after heating the package.

The Bottom Line

In conclusion, we would like to say that BGA soldering is a complicated procedure to understand. Only professionals in this field know it better than others. We hope you found this article helpful and informative.