What Are Polycarbonate Sheets Used For?

Polycarbonate sheets, also known as PC sheets or Lexan, are versatile building materials that have a range of uses in the construction and engineering industries. Polycarbonate is a thermoplastic polymer that has excellent properties including transparency, strength, and impact resistance.

It is available in many different formats including solid sheets, multiwall (honeycomb) structures, or flexible films.

Polycarbonate Uses

Glazing Panels

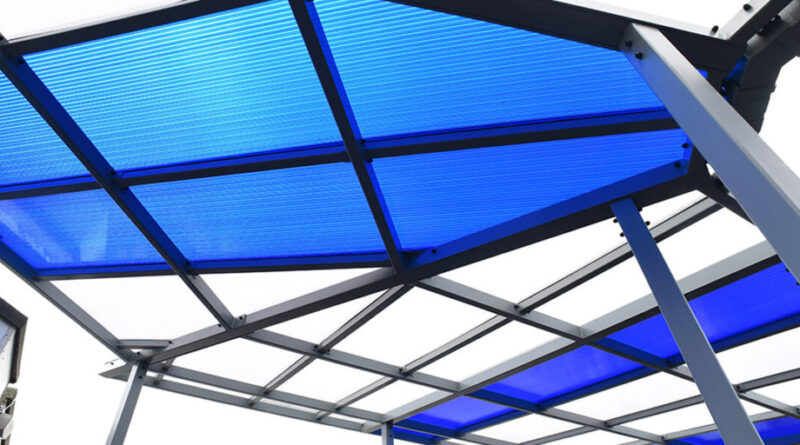

Polycarbonate sheets are commonly used as glazing panels in buildings to provide natural light while also offering protection from severe weather conditions such as hail, high winds, and other debris. They can be found on everything from skylights to patio covers due to their ability to maintain clarity over an extended period of time.

Roofing Projects

In addition to being used for glazing applications, polycarbonate sheets can also be used for roofing projects like carports and shed roofs. The lightweight material can easily be cut into various shapes which makes it easy to install and its high UV resistance ensures that colors won’t fade over time as some other materials do.

Automotive Industry

Another popular use for polycarbonate sheets is in the automotive industry where they are often employed as side-view mirrors or headlight lenses. In fact, Lexan has been the material of choice for manufacturers since the 1970s due to its superior shatter resistance compared to glass alternatives.

Aside from these more common uses, PC sheets are increasingly being employed in advanced manufacturing processes due to their superior machinability and weldability characteristics.

For example, they can be used as a moldable substrate when making fiberglass parts or as a clear cover layer when laser engraving logos onto products such as trophies and awards which require intricate details.

How Do Polycarbonate Sheets Compare to Glass and Acrylic?

Polycarbonate sheets are lightweight, flexible, and shatter-resistant compared to glass. Their transparency is also higher than that of acrylic. Polycarbonate sheets have better temperature resistance and flexibility than glass.

They can be used in temperatures ranging from -40°F to 248°F (-40°C to 120°C). Unlike acrylic plastic, polycarbonate is much stronger and more durable, making it the ideal material for safety shields, glazing applications, and structural uses where strength and impact resistance are important.

Another advantage is that polycarbonate sheets can be easily cut with standard tools like saws, routers, or laser cutters. The light transmission of polycarbonate sheeting makes them useful for lighting fixtures or signs as well as greenhouse applications. In addition, the sheets are also UV-stabilized for outdoor use and provide excellent insulation by blocking infrared light. This makes them suitable for energy-efficient applications such as windows or roofing materials.

In summary, polycarbonate sheets offer many advantages over glass or acrylic. They are lightweight, shatter-resistant, flexible, temperature resistant, and easily cut with standard tools. Their high transparency and UV stabilization make them a great choice for lighting fixtures or signs as well as greenhouse applications where energy efficiency is important.

Conclusion

Overall, polycarbonate sheeting is an incredibly versatile material with numerous applications across many different industries ranging from home construction projects to commercial manufacturing processes. It has become one of the most popular plastics on the market due to its extraordinary strength-to-weight ratio along with its ability to withstand extreme temperatures without becoming brittle or deteriorating with age.